In industrial projects, precision and accuracy are crucial for ensuring the overall quality of work. Whether you’re involved in construction, manufacturing, or any other field that requires exact measurements, using the right tools can make all the difference.

One such tool that has become essential in modern industrial work is the laser level. Laser leveling technology offers numerous benefits for increasing the efficiency, safety, and precision of projects. Here are five ways laser leveling can improve the quality of your industrial work.

1. Enhanced Precision and Accuracy

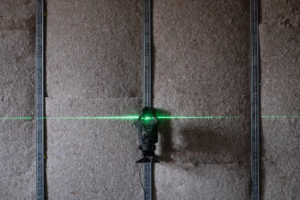

Laser levels are known for their exceptional accuracy, making them ideal for industrial applications where even a minor miscalculation can lead to significant errors. Traditional methods of leveling, such as bubble levels or manual measurements, leave room for human error.

In contrast, laser levels project a highly accurate and visible laser beam that can be used to ensure perfect alignment across large distances. This precision ensures that all components, whether in a construction site or manufacturing facility, are perfectly level or aligned, contributing to the overall quality and durability of the project.

2. Increased Efficiency

Using a laser level can dramatically speed up the process of leveling and aligning various elements in your work. Traditional leveling methods can be time-consuming, often requiring multiple adjustments and double-checking.

With a laser level, the process becomes much faster and more efficient, as the laser provides a clear, continuous line for guidance. This allows workers to focus on their tasks without constantly stopping to verify measurements manually.

3. Consistency Across Large Areas

In industrial work, especially in large-scale construction projects, maintaining consistency across a vast area is crucial. Laser levels are capable of projecting level lines over long distances with minimal deviation, ensuring that large surfaces, such as floors, walls, or foundations, are uniformly level.

This consistency is particularly important in industries like civil engineering, where uneven surfaces can compromise the structural integrity of a building or installation.

4. Finding Laser Levels for Sale

When it comes to choosing the right laser level for your industrial needs, finding the right model at a reasonable price is essential. Many specialized retailers and online marketplaces offer a wide range of Laser levels for sale, from basic models for small-scale tasks to advanced systems designed for large industrial projects.

Before purchasing, it is important to evaluate your specific requirements, such as the distance you need the laser to cover, the environment in which it will be used, and the precision required.

5. Improved Safety on the Job Site

Safety is always a top priority in any industrial environment, and laser leveling tools can play a key role in ensuring a safer workplace. Traditional leveling methods often involve moving heavy equipment, climbing ladders, or bending into awkward positions to make measurements—all of which increase the risk of injury.

Laser levels, however, can be set up in one position and used to project lines over long distances without the need for constant repositioning. This minimizes physical strain on workers and reduces the chances of accidents or mistakes caused manual adjustments, contributing to a safer and more efficient work environment.